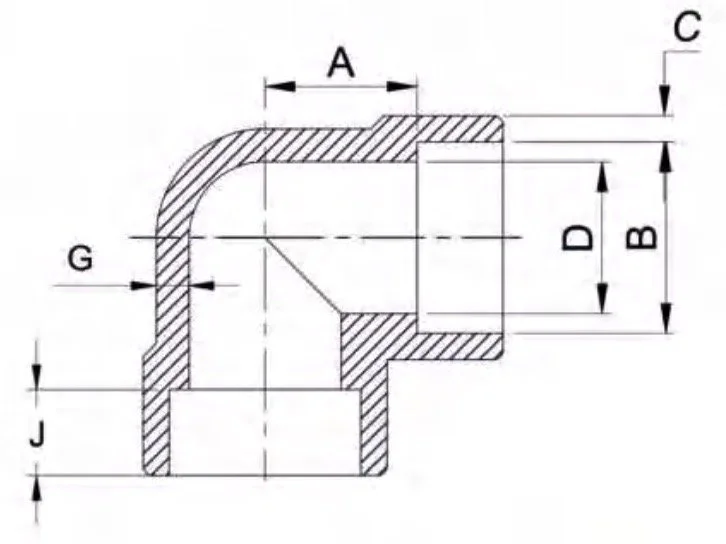

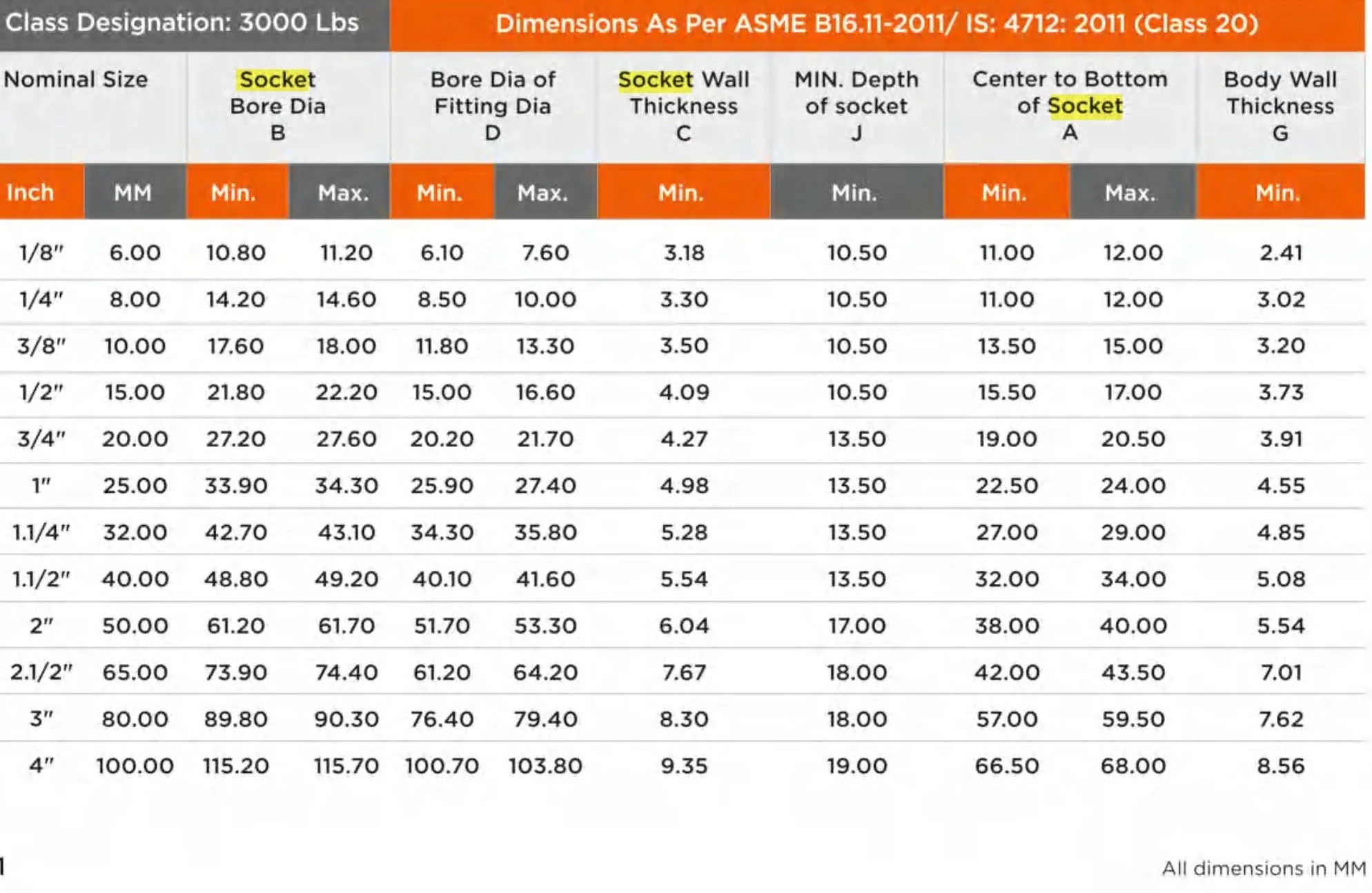

VS MS Forged Socket Weld Elbow 3000#

A forged socket weld elbow is a type of pipe fitting that is designed to change the direction of flow in a piping system. The term "forged" refers to the manufacturing process used to create the elbow. Forged fittings are made by heating a piece of metal and then shaping it into the desired form through the use of a press or hammer. This process results in fittings that are generally stronger and more durable than other types of fittings, such as those made through casting.

The term "socket weld" refers to the type of connection used to attach the elbow to the piping system. Socket weld fittings have a recessed area that is designed to accept the end of the pipe. The pipe is then welded into the socket using a process called "fillet welding," which involves the use of a fillet weld to connect the pipe and fitting. This creates a strong and leak-proof joint.

The term "3000#" refers to the pressure rating of the elbow. In this case, the MS Forged Socket Weld Elbow 3000# is designed to withstand pressures of up to 3000 pounds per square inch. This makes it suitable for use in high-pressure piping systems, such as those found in the oil and gas industry or in power generation plants.

When used in conjunction with other high-quality piping components, the MS Forged Socket Weld Elbow 3000# can help to ensure the safe and efficient operation of piping systems in a variety of industries.

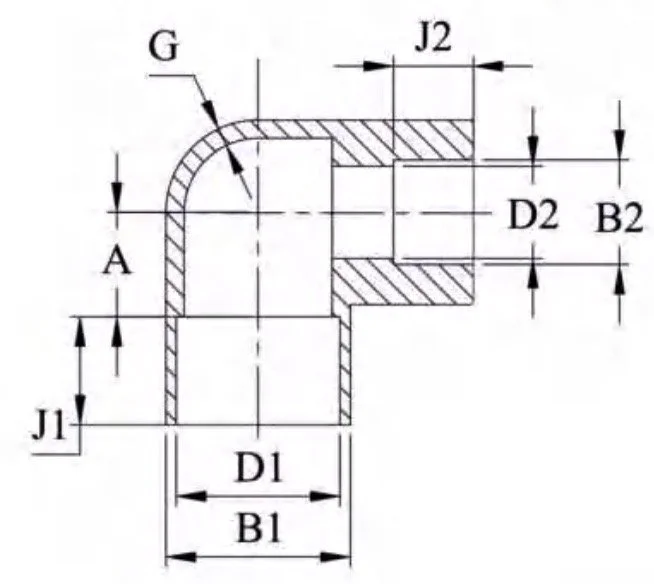

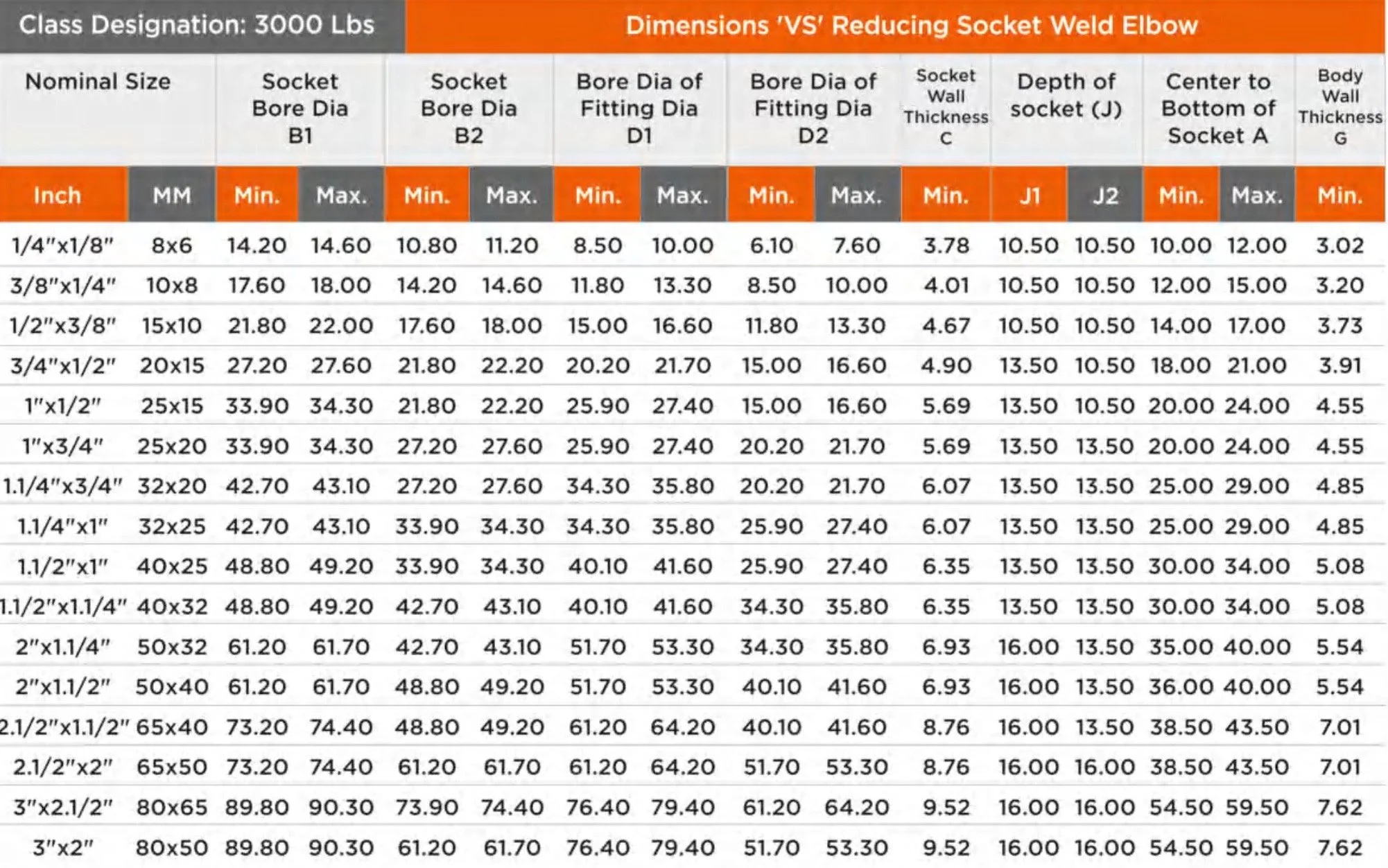

VS MS Forged Socket Weld Reducing Elbow 3000#

The MS Forged Socket Weld Reducing Elbow 3000# is a type of pipe fitting designed to connect pipes of different diameters at an angle while maintaining high-pressure integrity. It is made through the forging process, which ensures strength, durability, and resistance to deformation and cracking. The 3000# rating indicates that it can withstand pressures of up to 3000 pounds per square inch, making it suitable for use in high-pressure piping systems.

The reducing elbow is called such because it has different-sized openings on either end, which allow for the connection of pipes of different sizes. The larger end is usually used to connect to the larger diameter pipe, while the smaller end connects to the smaller diameter pipe. This allows for a smooth transition between the pipes, preventing any obstruction or turbulence in the fluid flow.

Like other socket weld elbows, the MS Forged Socket Weld Reducing Elbow 3000# uses a socket weld connection to attach the fitting to the piping system. This creates a strong and leak-proof joint, ensuring that the system remains free of leaks, which can be costly and dangerous.

The reducing elbow is commonly used in industries such as oil and gas, chemical, and petrochemical, where the piping systems require the connection of pipes of different sizes. It is available in a range of materials, such as carbon steel and stainless steel, to suit various applications.

In conclusion, the MS Forged Socket Weld Reducing Elbow 3000# is a reliable and durable pipe fitting that is designed for use in high-pressure piping systems. Its ability to connect pipes of different diameters while maintaining high-pressure integrity and its strength, durability, and resistance to deformation and cracking make it a valuable component in a variety of industries.