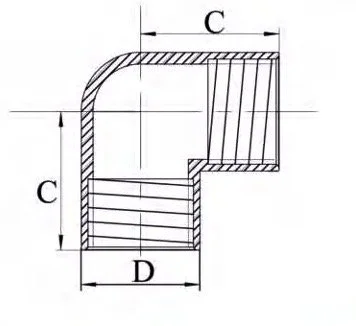

VS MS Forged Elbow 90° LBS Black 1000

When it comes to piping systems, fittings play a critical role in ensuring a safe and efficient flow of fluid or gas. One of the most used fittings is the elbow, which is used to change the direction of the pipe.

The 90° elbow is a standard fitting that changes the direction of the pipe by 90 degrees. The most common use for a 90° elbow is in fire fighting, plumbing and HVAC systems, where it helps to redirect the flow of fluid or gas around obstacles or corners.

Forged fittings are made by heating a piece of metal and then pounding it into the desired shape. This process creates a fitting that is stronger and more durable than a cast fitting, making it ideal for high-pressure applications. The term "1000 lbs" refers to the maximum pressure that the fitting can withstand, making it suitable for use in a variety of industries, including oil and gas, chemical processing, and power generation.

The black coating on the fitting provides additional protection against corrosion, making it ideal for use in harsh environments.

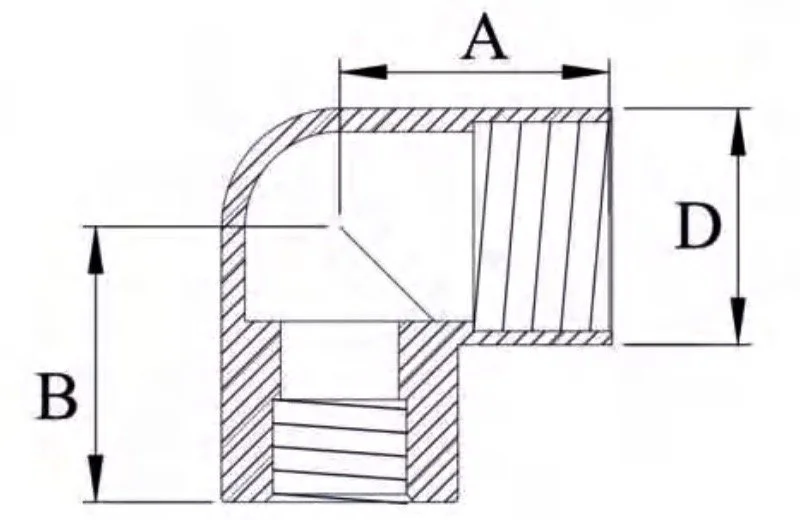

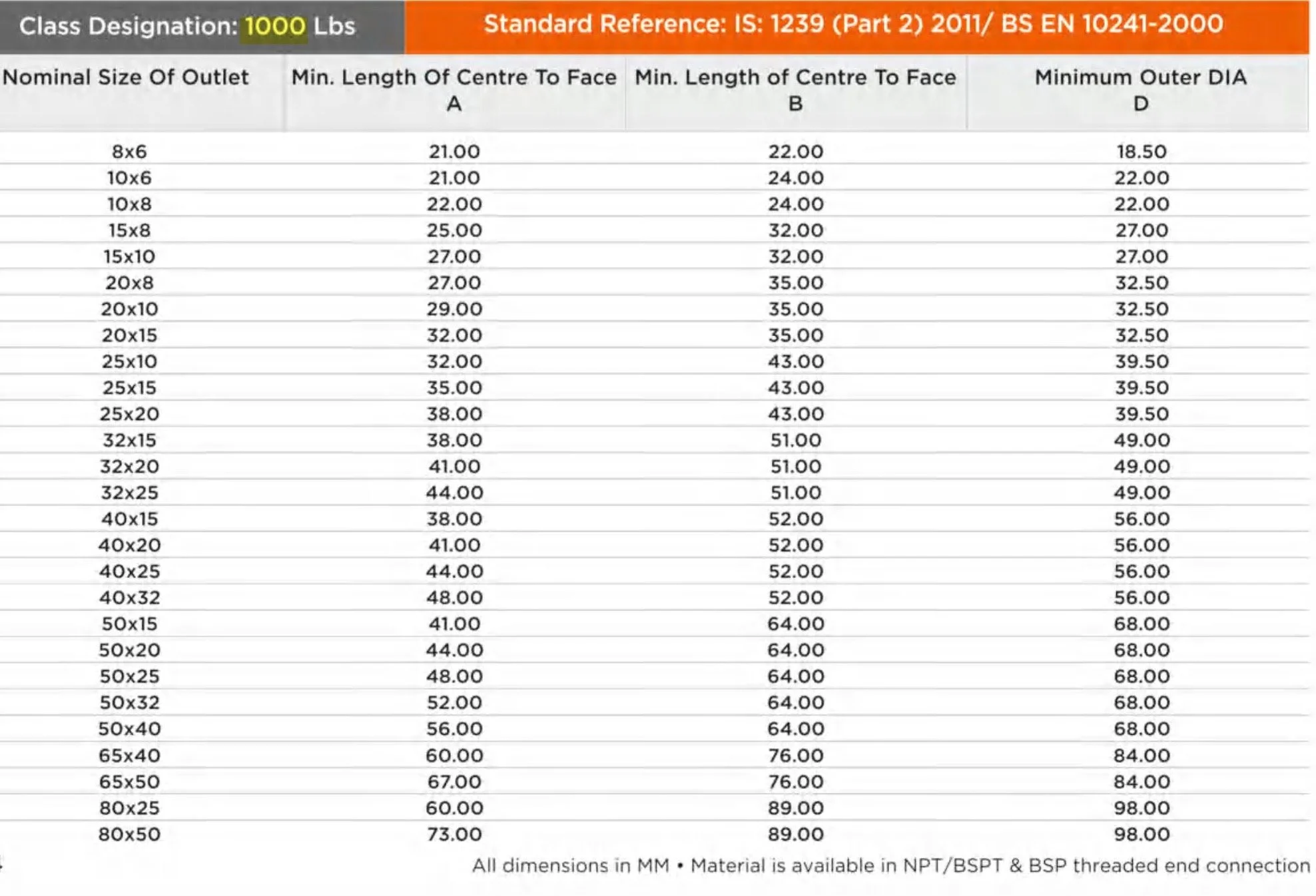

VS MS Forged Reducing Elbow Threaded 1000# Equal OD

The MS forged reducing elbow threaded is a type of elbow that is used to connect two pipes of different diameters. It is available in various materials such as stainless steel, carbon steel, and brass, and in different sizes and schedules to fit a wide range of piping systems. The most common use for a reducing elbow is in plumbing and HVAC systems, where it helps to connect pipes of different sizes.

The MS forged reducing elbow threaded is a versatile fitting that offers a range of advantages in piping systems. Its compatibility, strength and durability, corrosion resistance, easy installation, and cost-effectiveness make it a popular choice for many applications.