Boiler Manufacturers in India: An Extensive Guide for 2024

As India positions itself at the forefront of industrial innovation and growth, boilers have become an indispensable asset for myriad industrial operations. These critical components are essential for steam generation and heating applications, which are pivotal across a wide array of sectors. The burgeoning economic landscape has significantly heightened the demand for efficient, high-quality boilers. This demand underscores the importance of selecting a manufacturer that not only meets but exceeds expectations in terms of performance and return on investment (ROI).

Comprehensive Introduction

Boilers, essentially sophisticated pressure vessels, are engineered to heat water or generate steam. This steam or hot water plays a vital role in heating, sterilization, and power generation across various sectors, including but not limited to power generation, oil & gas, chemical, textiles, and automotive industries. Their ubiquitous application makes them a cornerstone of industrial functionality.

Predictions for the Indian boiler market indicate an upward trajectory, with an expected compound annual growth rate (CAGR) of more than 8% from 2022 to 2027. This growth is fueled by an amalgamation of factors such as burgeoning manufacturing activities, escalating energy requirements, and comprehensive urbanization initiatives. Moreover, government initiatives like "Make in India" have revitalized the domestic manufacturing sector, significantly amplifying the demand for robust boilers.

This detailed exploration aims to navigate the complex landscape of boiler manufacturers in India, spotlighting those that deliver advanced, cost-effective solutions compliant with the Indian Boiler Regulations (IBR) standards. A thorough examination of boiler types, prominent manufacturers, and a guide to selecting an appropriate supplier for specific requirements is provided.

Detailed Overview of Boiler Varieties in India

In-depth Look at Industrial Boilers

Industrial boilers are pivotal in manufacturing and processing industries, with their design and structure varying widely. Prominent types include:

Water Tube Boilers: These are optimal for applications requiring high pressure and large capacities, offering rapid heat transfer.

Fire Tube Boilers: Best suited for spaces where compact boilers are needed, these are ideal for low to medium steam outputs.

Packaged Boilers: Pre-assembled and installation-ready, these boilers are perfect for operations with small steam requirements.

Comprehensive Insight into Commercial Boilers

These boilers are primarily used in commercial settings such as hotels, hospitals, and educational institutions. Types include:

Electrical Boilers: Highlighting simplicity and environmental benefits, these boilers utilize electricity for operation.

Oil & Gas Fired Boilers: These boilers are efficient and provide controlled heating using various fuels.

Distinction Between IBR and Non-IBR Boilers

IBR Boilers: Adhering strictly to Indian Boiler Regulations, these are mandatory for certain high pressure and capacity applications.

Non-IBR Boilers: Suitable for lower pressure applications, these boilers are not regulated by IBR standards.

Exhaustive List of Top Boiler Manufacturers in India

The Indian market boasts a plethora of boiler manufacturers, each offering unique solutions. Among the elite are:

| Company | Notable Products |

|---|---|

| Thermax Limited | Packaged boilers, heat recovery steam generators |

| Forbes Marshall | Steam boilers, thermic fluid heaters, heat exchangers |

| Cheema Boilers Limited | Coil type IBR/non-IBR steam boilers |

| VPI Engineering | Waste heat recovery boilers, fired heaters, and thermal oxidizers |

| Exothermics India | Hot water boilers for chemical and hydrocarbon processing industries |

| Thermodyne Engineering System | Vertical multi-fuel IBR/non-IBR steam boilers |

| Indeck Power Equipment Company | Waste heat boilers, fired packaged boilers, heat recovery steam generators |

| Industrial Boilers Ltd | Solid fuel-fired boilers, fluidized bed combustion boilers |

| Vijay Engineering | Industrial boilers, HRSGs, thermic fluid heaters, solar equipment |

| Everest Boilers | High pressure packaged boilers, heat exchangers, and economizers |

These manufacturers stand out for their commitment to quality and their ability to tailor solutions to specific industrial requirements.

Key Considerations for Selecting a Boiler

The process of selecting the right boiler encompasses numerous factors:

Specific Use: The intended application significantly influences the choice of boiler type and capacity.

Operating Conditions: The required steam parameters dictate the operating pressure of the boiler.

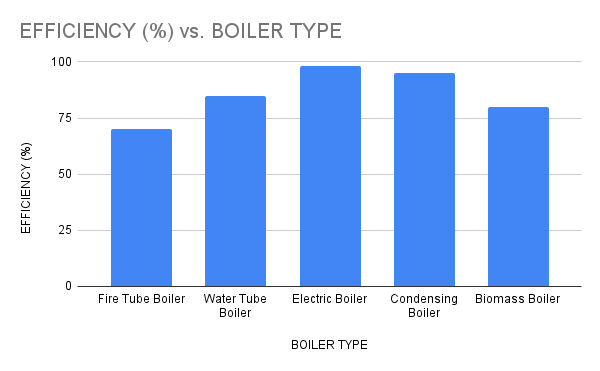

Efficiency Metrics: High-efficiency boilers are preferable for their potential to reduce fuel costs significantly.

Technological Integration: Modern boilers equipped with advanced control systems offer superior safety and efficiency.

Support Services: The availability of a robust after-sales service network is critical for ongoing operational success.

Financial Planning: It is essential to consider both the initial investment and the operational costs over the boiler's lifespan.

Regulatory Compliance: Ensuring that the boiler meets all relevant standards and certifications is crucial for safe and efficient operation.

Extensive Conclusion and Recommendation

The surge in industrial activities across India signals a burgeoning demand for high-performance boilers. Aligning with a manufacturer renowned for reliability and quality is key to enhancing operational efficiency and securing a competitive edge. In this context, Vijay Sales Corporation emerges as a premier supplier, offering an extensive array of seamless pipes at competitive rates, perfectly suited for boiler applications. Their comprehensive MSL price list provides a transparent overview of options, ensuring that businesses can make informed decisions tailored to their specific